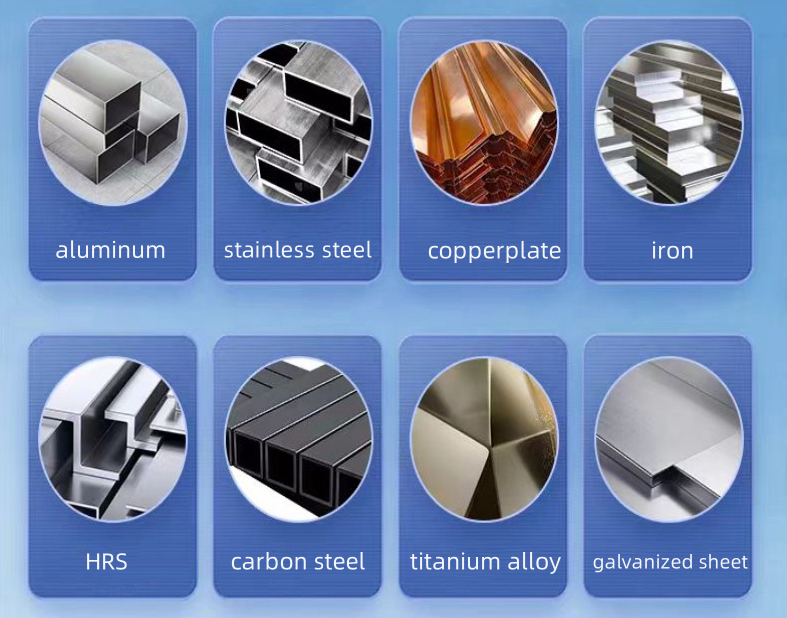

1. Intsimbi engatyiwayo

Insimbi engenasici ine-coefficient ephezulu yokwandiswa kwe-thermal, kwaye ijwayele ukutshisa ngexesha le-welding. Xa indawo echaphazeleke bubushushu incinci, iya kubangela iingxaki ezinzulu zokuguqula. Nangona kunjalo, ubushushu obuveliswa ngumatshini we-laser welding we-handheld ngexesha lenkqubo yonke ye-welding iphantsi. Idityaniswe ne-conductivity ephantsi ye-thermal, izinga eliphezulu lokufunxa amandla kunye nempumelelo yokunyibilika kwensimbi engenasici, eyenziwe kakuhle, i-welds egudileyo kunye nenhle inokufumaneka emva kwe-welding.

2. Intsimbi yekhabhoni

Intsimbi yekhabhoni eqhelekileyo inokudityaniswa ngokuthe ngqo ngesandlaIFayibha laser welding Machine, umphumo uthelekiseka ne-stainless steel welding, kwaye indawo echaphazelekayo ukushisa incinci, kodwa xa i-welding medium kunye ne-carbon steel high, ukushisa okushiyekileyo kuphezulu kakhulu, ngoko ke kusafuneka ukuba udibanise phambi kwe-welding. Ukushisa kwangaphambili kunye nokugcinwa kobushushu emva kwe-welding ukukhulula uxinzelelo kunye nokuphepha iintanda. Apha singakwazi ukuthetha ngomatshini we-welding obandayo. Intsimbi ephakathi kunye nephezulu yekhabhoni inokudityaniswa okanye ilungiswe ngesantya esicothayo kunye ne-welding ebandayo kunye nentsimbi yokuphosa intsimbi. Ngokubhekiselele kulawulo lobushushu, ulawulo lobushushu, kunye nolawulo lobushushu, umatshini wokuwelda obandayo unokufundisa i-laser welding ebambe ngesandla isebenze ngokufanelekileyo kwintsalela yobushushu emva kwe-welding.

3. Die intsimbi

Kufanelekile ukuwelda iintlobo ezahlukeneyo zentsimbi yokufa, kwaye umphumo we-welding ulungile kakhulu.

4. I-Aluminiyam kunye ne-aluminium ingxubevange

I-aluminium kunye ne-aluminium alloys zizinto ezibonisa kakhulu, kwaye i-porosity inokuvela kwi-pool etyhidiweyo okanye kwiingcambu ngexesha le-welding. Xa kuthelekiswa nezixhobo zetsimbi zangaphambili, i-aluminium kunye ne-aluminium alloys ineemfuno eziphezulu zeeparitha, kodwa nje ukuba iiparamitha ezikhethiweyo ze-welding zifanelekile, i-weld seam eneempawu ezifanayo zokwenza isiseko sesinyithi sinokufumaneka.

5. Ubhedu kunye ne-alloy yobhedu

I-thermal conductivity yobhedu inamandla kakhulu, kwaye kulula ukubangela ukungena okungaphelelanga kunye nokudibanisa inxalenye ngexesha le-welding. Ngokuqhelekileyo, izinto zobhedu zifudumala ngexesha lenkqubo ye-welding ukuncedisa i-welding. Apha sithetha ngezinto zobhedu ezibhityileyo.Umatshini wokuwelda welaser obanjwe ngesandlacan ngqo iWelding, ngenxa yamandla ayo agxininisiweyo kunye nesantya se-welding ekhawulezayo, ayichatshazelwa kangako yi-thermal conductivity ephezulu yobhedu.

6. Ukuwelda phakathi kwezinto ezingafaniyo

Umatshini we-laser welding welding unokuqhutywa phakathi kweentlobo ezahlukeneyo zetsimbi ezingafaniyo, ezifana ne-copper-nickel, i-nickel-titanium, i-copper-titanium, i-titanium-molybdenum, i-brass-copper, i-carbon steel-copper ephantsi kunye nezinye iintsimbi ezingafaniyo. I-laser welding inokuqhutywa phantsi kwayo nayiphi na imeko (igesi okanye ubushushu).

Umatshini wokuwelda welaser ophathwa ngesandlasithetha nje imveliso esetyenziswa ngokubanzi kwishishini lokuwelda, ikakhulu kuba nangona esi sixhobo sikhangeleka kubiza kakhulu, sinokonga iindleko zabasebenzi kakuhle kakhulu. Iindleko zomsebenzi weentsimbi zixabisa kakhulu. Ukusebenzisa oku Imveliso isombulula ingxaki yokuqashwa kwamaxabiso abizayo kwaye anzima. Ngapha koko, umatshini we-laser welding obambe ngesandla uphumelele indumiso evumelanayo kumawakawaka abathengi ngenxa yobomi bayo obude kunye nokusetyenziswa kwamandla aphantsi.

Ukuba ufuna ukufunda ngakumbi malunga nokucoca i-laser, okanye ufuna ukukuthengela umatshini wokucoca i-laser, nceda ushiye umyalezo kwiwebhusayithi yethu kwaye usithumelele i-imeyile ngqo!

Ixesha lokuposa: Dec-25-2024